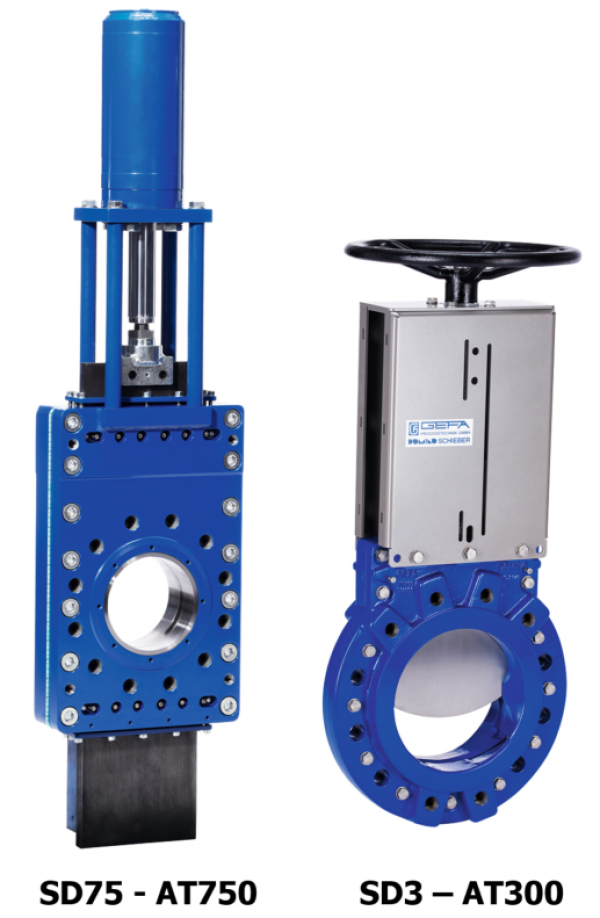

GEFA ball valve DG1 made of 1.4529

Corrosion-resistant three-piece ball valve made of 1.4529

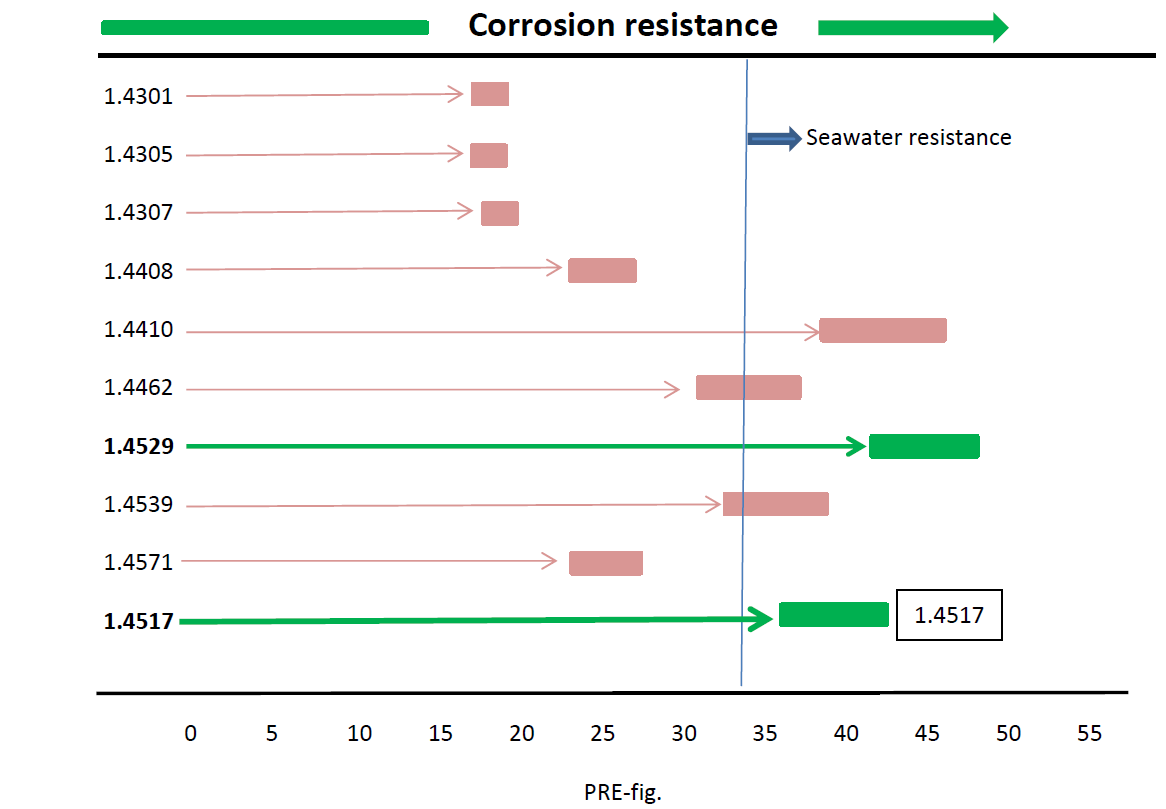

With the continuous progress in industrial technology, the need for materials and technologies that meet the highest demands is also growing. This need is particularly evident when dealing with corrosive applications. In this context, the three-piece ball valve of the DG1 series stands out, which is made of the particularly corrosion-resistant material 1.4529 and was specially developed for such demanding areas of application.

Industrial progress through corrosion resistance

In key modern industries such as the chemical, oil and gas as well as water treatment industries, corrosion resistance and reliability are crucial. Choosing the right materials and components can make the difference between smooth running operations and costly downtime. This is where the corrosion-resistant three-piece ball valve made from 1.4529 plays a key role. But what makes this material and this ball valve so special and how can it help you?

GEFA ball valve DG1 made of 1.4529

As a German manufacturer of industrial valves, we have set ourselves the challenge of providing high-quality, corrosion-resistant materials for the most demanding applications. The three-piece ball valve from the DG1 series has also been available for some time in the material variant 1.4529 and can be supplied with short delivery times. This high-alloy super austenite offers exceptional resistance to pitting, stress corrosion and crevice corrosion.

Alloy 926: The solution for demanding conditions

1.4529 (Alloy 926) is a highly alloyed, stainless super austenite with a high molybdenum content and low nitrogen content. This special chemical composition gives the material its outstanding corrosion resistance and makes it the preferred choice for applications where conventional stainless steels reach their limits.

- Material: 1.4529 (Alloy 926)

- Resistance: High resistance to pitting, stress corrosion and crevice corrosion

- Chemical composition: High molybdenum content, low nitrogen content

- Construction: Three-part design for easy maintenance and high reliability

The GEFA ball valve series DG1 made of 1.4529, designed, built and tested in Dortmund, meets the requirements for safety and reliability in plant engineering.

Your advantages at a glance

Automation

Our products offer comprehensive automation solutions that meet the highest standards. The standard mounting flange in accordance with EN ISO 5211 enables direct actuator mounting without interrupting the stem. Depending on requirements, pneumatic, electric or manual actuators can be used.

Safety

In terms of safety, our products are characterized by ease of maintenance thanks to the spring-loaded V-rings made of PTFE or graphite packings. A TA-Luft is also available as an option to ensure additional safety.

Primary sealing

The internal primary sealing, combined with anti-blowout stem, ensures leakage-free operation. This combination guarantees reliable tightness and safety, even with high switching frequencies.

Body seal

The separate, fully encapsulated body seal ensures a secure sealing.

Service-friendly and exact mounting

Our products are particularly easy to service and precise to install. The fully centered screw guide guides the middle section precisely to the flanges, which enables optimum storage and easy installation.

Shut-off valve

The surface of the ball is high-gloss polished and is characterized by an extremely precise contour accuracy, which guarantees exact roundness.

Seat ring

The seat rings ensure absolute tightness in the passage thanks to their special form. The preload of the seat rings causes a spring effect that enables reliable sealing in all pressure ranges. Available materials: PTFE, PTFE/glass, PTFE/carbon, PEEK, UHMWPE, POM and PVDF.