H2-ready Valves

Reliable valves for hydrogen technology

What does H2-ready mean?

With the growing interest in climate-friendly energy solutions, the focus is increasingly shifting to hydrogen as a key technology. When the term “H2-ready” is used, it means that systems and components are specially designed to meet the requirements of hydrogen applications. However, it is important to note that the term “H2-ready” may merely be a marketing statement that should be checked. As an industrial valve manufacturer, we have risen to this challenge and designed our valves specifically to meet the requirements of hydrogen technology. Through targeted material selection, extensive testing and compliance with relevant norms and standards, we can ensure that our products can withstand the special conditions of hydrogen applications.

GEFA - Your experts for H2-ready valves

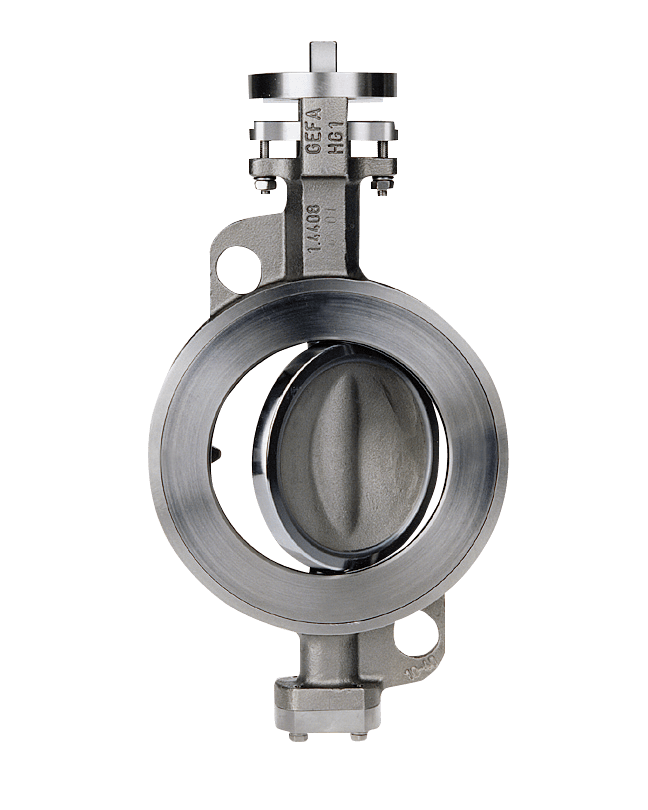

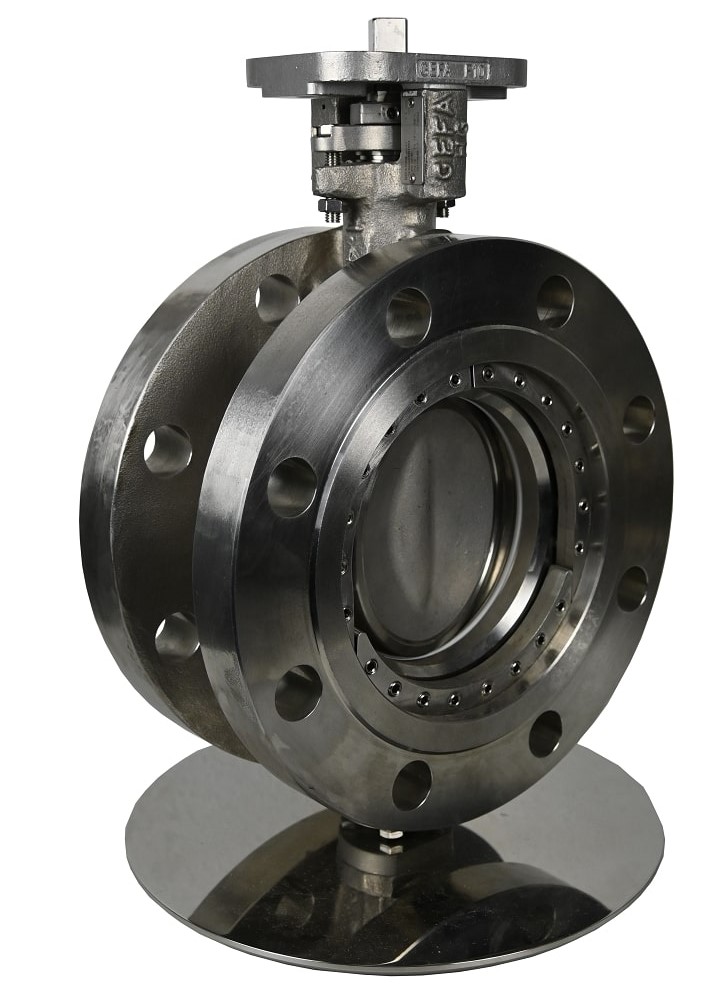

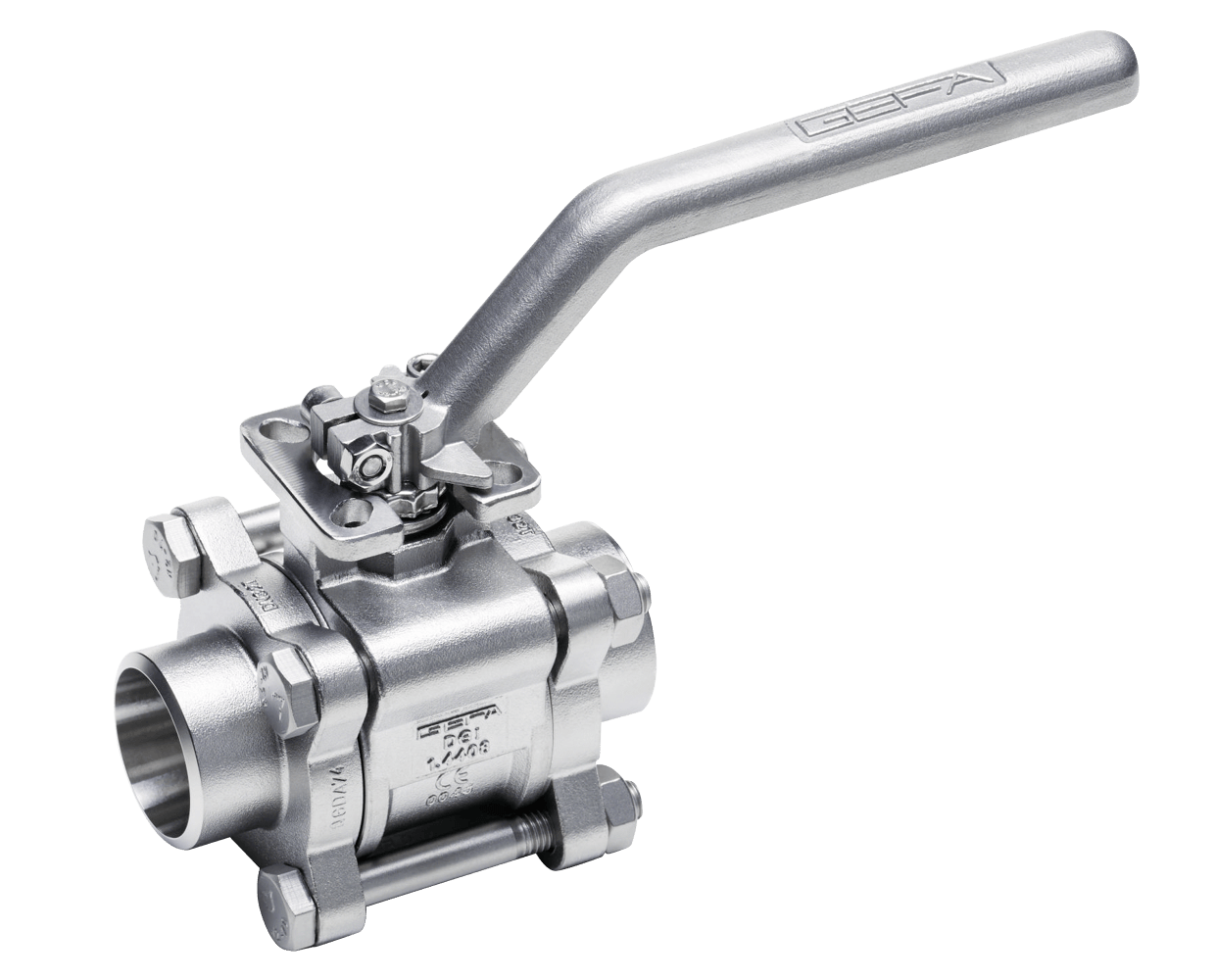

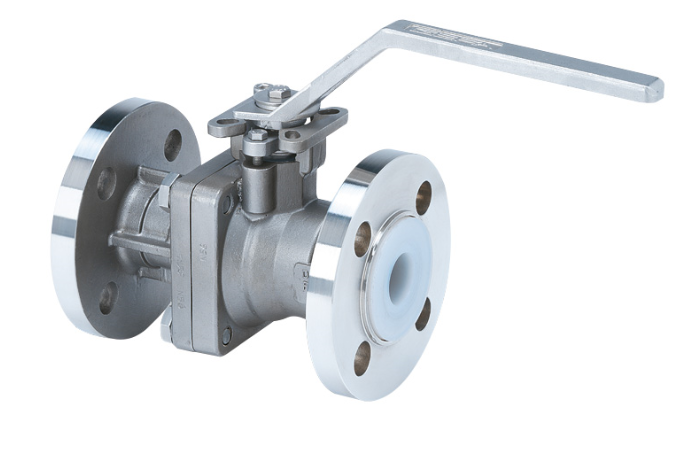

We offer a wide range of products that are specially designed for use in hydrogen applications. From ball valves and high-performance butterfly valves to double-flanged high-performance butterfly valves - at GEFA you will find the right solutions that are optimally adapted to the special properties of hydrogen. But what makes GEFA products so special?

Product features at a glance:

- Tightness: Absolute tightness on the inside and technically permanent tightness on the outside to ensure the high purity of the hydrogen.

- Material properties: High-quality, corrosion-resistant materials that can withstand the specific requirements of hydrogen, including resistance to hydrogen embrittlement.

- Pressure resistance: Developed for high-pressure applications to meet the demanding requirements of modern hydrogen technology.

- A wide range of applications: From DN 8 to DN 800, we can offer you the ideal solutions for the transportation, storage and use of hydrogen in industrial processes.

Discover more on our hydrogen page

Are you curious to find out more about our expertise in the field of hydrogen? On our hydrogen page you will find detailed information, product descriptions and relevant application examples. You are also welcome to send us a message directly via the e-mail address

Conclusion

H2-ready valves are an indispensable component of modern hydrogen technology and play a decisive role in the realization of the energy transition. GEFA is at your side as a competent partner when it comes to finding solutions that meet the highest standards.